Rivet Nut Tool

Product Details:

- Usage Industrial

- Product Type Rivet Nut Tool

- Color Blue

- Click to View more

Rivet Nut Tool Price And Quantity

- 27000 INR/Piece

- 1 Piece

Rivet Nut Tool Product Specifications

- Rivet Nut Tool

- Industrial

- Blue

Rivet Nut Tool Trade Information

- Paypal, Cash Advance (CA), Cash in Advance (CID), Cheque

- Days

- Yes

- If order is confirmed we will reimburse the sample cost

- Asia

- All India

Product Description

A rivet nut tool, also known as a rivnut or nutsert tool, is designed to install rivet nuts”threaded inserts that enable fast and reliable bolting in thin materials where traditional tapping may not be possible. Commonly used in automotive, aerospace, manufacturing, and DIY applications, rivet nuts create secure and reusable threads in sheet metal, fiberglass, plastic, and other materials.

Key Features and Components:

1. Mandrel and Nosepiece: The tool has interchangeable mandrels and nosepieces to accommodate different sizes of rivet nuts, typically ranging from small (M3) to large (M12) sizes.

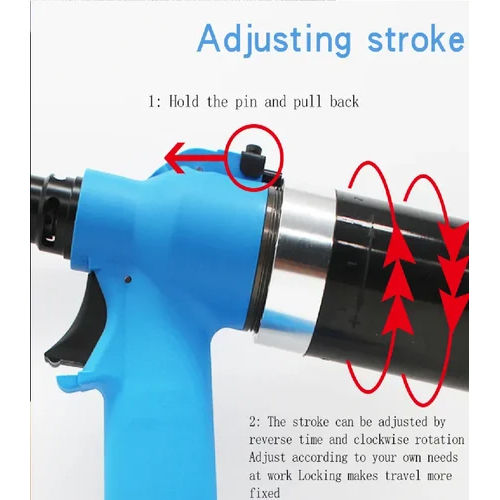

2. Installation Mechanism: The tool expands the rivet nut in the material, locking it securely to create a durable, threaded insert.

3. Power Type:

Manual: Suitable for light-duty applications; operates by squeezing handles.

Pneumatic: Connects to an air compressor for faster, less labor-intensive operation, ideal for high-volume or industrial tasks.

Cordless: Battery-operated for mobility and ease, combining power with convenience.

4. Ergonomic Design: Handles are often ergonomically designed for comfort, minimizing strain during repeated use.

Advantages:

Versatility: Allows bolting in thin materials without distortion.

Strength: Provides a strong threaded insert in materials where conventional bolts can't be used.

Reusable Threads: Unlike rivets, rivet nuts create reusable threads, making disassembly and reassembly easy.

Common Applications:

Automotive bodywork and customizations

Aerospace panel fastening

Furniture and cabinetry assembly

Electronics and appliance assembly

This tool is ideal for any situation requiring a threaded insert in materials that are too thin for traditional threading or where backside access is limited.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Pneumatic Tools and screwing' category

|

KAASU ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |